Nothing Found

Sorry, no posts matched your criteria

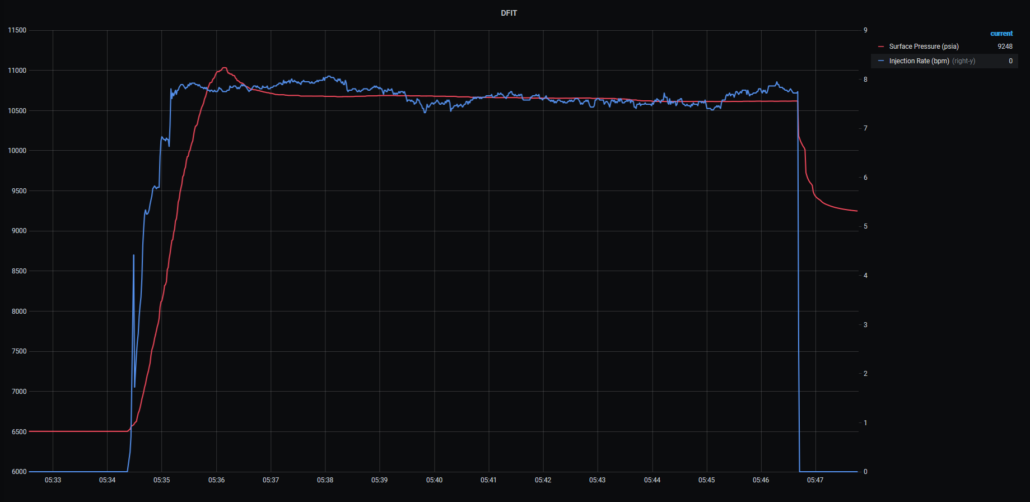

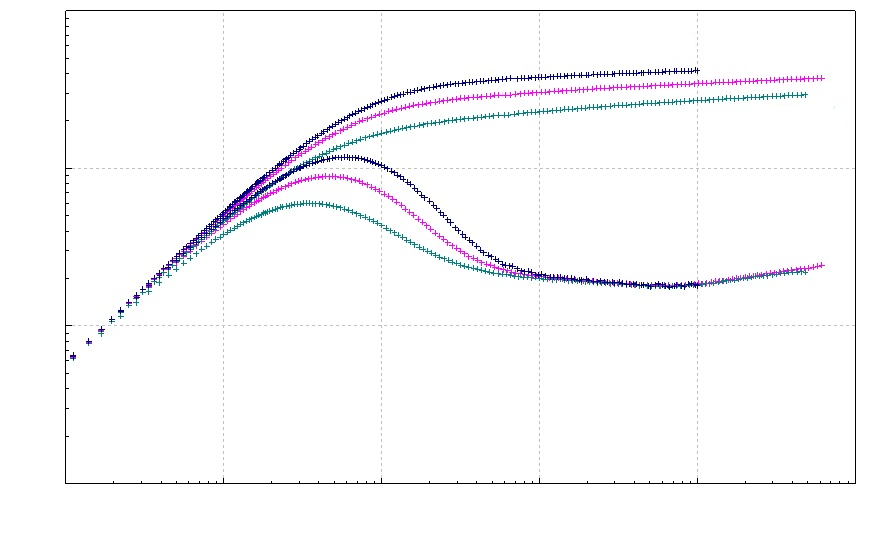

Diagnostic Fracture Injection Tests (DFIT) have become a standard practice in pressure transient testing and in the planning of efficient well stimulation. DFIT’s can be used as a low cost, non-invasive method to determine reservoir pressure, permeability, fracture gradients, and fracture closure pressure to maximize savings on frac designs. Testing across a development area can also help illuminate possible pressure depletion between parent-child wells.

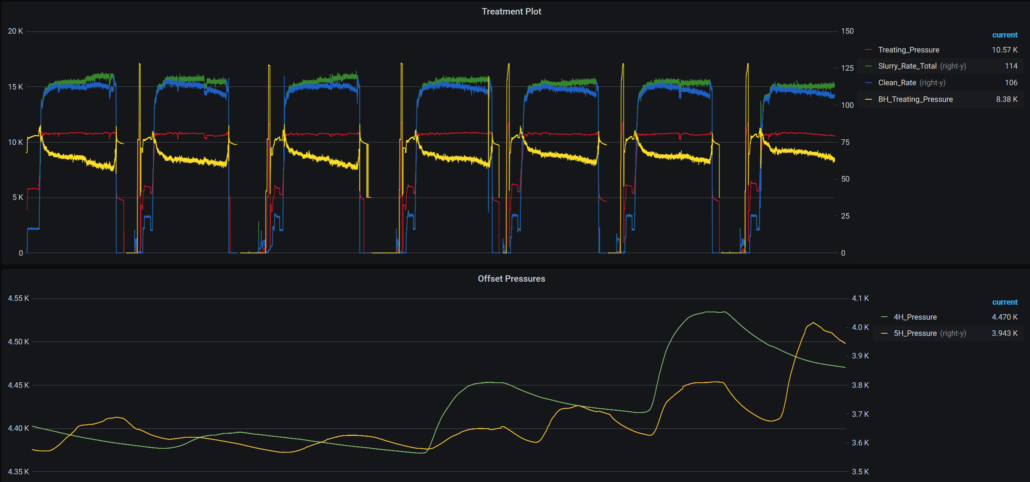

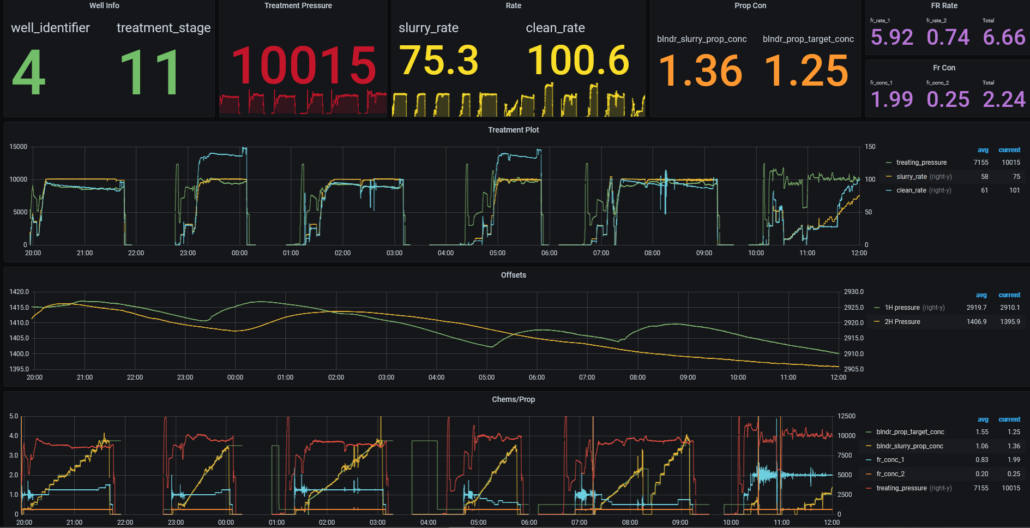

Recording and streaming pressure data of clustered wells that are offset to wells being fractured can reveal inter-well pressure interference/communication in certain zones and can lead to corrective measures to optimize well spacing and maximize production. In a time where it is not uncommon to see several wells drilled on a single pad, monitoring your offset wells for interference is more important than ever.

Sorry, no posts matched your criteria

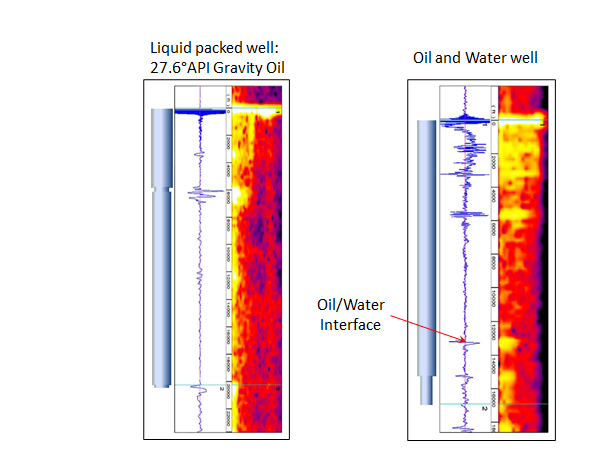

Whether determining Bottom hole pressure, monitoring overbalance on a low-pressure recompletion, optimizing artificial lift, or even determining pipe restrictions, acoustic shots can be very versatile. It is a non-intrusive way to understand fluid levels and id profiles in wells.

Sorry, no posts matched your criteria

By tying into existing DAQ in van/laptop we provide you with real-time, unbiased, raw data to all your desired treatment channels on Frac, Wire, and Coil vans. RDS frac van monitoring system seamlessly time synchronizes with offset pressure data captured by RDS surface gauges to monitor frac stimulation on adjacent wells.

There are only a few times that you can obtain an accurate reservoir pressure: during a DFIT or when you shut-in a well. If you are shutting in your wells, seize this opportunity to acquire an accurate reservoir pressure. Understanding reservoir pressure is central to improving every part of your strategy—from reserves to completions to production.

.

Proper management and monitoring of tank levels can help you reduce the cost of your operations and by using our tank level monitoring services, you gain access to your data in real-time which improves both efficiency and productivity. In addition, automated alerts can be set up to notify staff of potential issues, allowing you to respond to these conditions before they become critical.

We have the potential to monitor nearly any application and provide you with real-time high resolution/high-quality data. Let us know what your needs are and we will make it happen.

Mailing Address

P.O. BOX 660

Katy, Tx 77492

Contact By Phone

Phone: (281) 665-1200

Fax: (281) 665-1545

Real-Time DFIT Data – A Case Study

Several months ago, Reservoir Data Systems was called upon by a notable client to provide real-time solutions on a large-scale data project. The client allocated an annual budget of $500k for the project, with the hopes of capturing DFITs on 50 wells ($10k being the average expected cost per gauge rental per test). Using memory […]

SPE DFIT Conference Takeaways

Two weeks ago, Reservoir Data Systems sponsored a DFIT Processes and Applications SPE Workshop in Houston and it was a huge success! Over 90 industry experts, experienced engineers, and distinguished academics came together to share best practices and provide valuable insights. Before the workshop, I spoke to various reservoir and completion engineers from different […]

Decrease Costs and Downtime with Real-Time DFIT Data

Have you ever found yourself sitting in your office wondering how the DFIT you pumped last week was going on your well a thousand miles away? How do you check it? How do you know where you’re at in your test? In the year 2015, we still rely on simple surface and downhole pressure memory gauges […]