Bottom-hole Pressure Determination

The ABOT was developed initially as a safer, more economic means of determining bottom-hole well pressures. Oftentimes customers are uncertain of the presence of a liquid level in a well, which can lead to the miscalculation of bottom-hole pressure. Combining our EBOT and ABOT systems, we verify the presence of a potential fluid level and incorporate it into bottom-hole pressure calculations. This increases the accuracy of the calculated bottom-hole pressure and the applicability of the surface pressure testing.

Fluid Level Determination

On occasion, our customers will come across a well that is underperforming due to the loading of a liquid column. In gas wells, the ABOT system is used by our skilled technicians to first identify the severity of liquid loading, allowing customers to quickly plan a course of remediation, and then to monitor the progress of the recourse. In oil wells, found liquid levels can help customers determine a well’s producing rate efficiency and maximum production potential.

Obstruction Location

Another cause of decline in production can be a blockage somewhere downhole constricting or, in extreme cases, totally ceasing flow. Scale, paraffin, and other natural deposits are common blockages that can be successfully remedied using common practices once located using our ABOT system. Other debris, such as lost fishing tools, stray pipe, or broken wireline, are also easily located using our system.

Other ABOT applications

- Artificial Gas Lift efficiency testing

- Packer integrity testing

- Hole in tubing, casing, pipeline, or vessel location

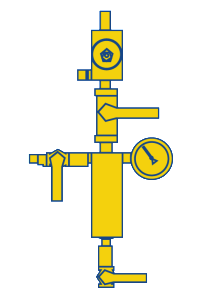

Benefits of ABOT Acoustic Well Survey System

- Wide range of applications

- All tests performed by highly skilled technicians, ensuring best possible data

- Can be operated manually by technicians for short term testing, or automatically for continuous testing over a longer duration.

- Minimal size, sturdy housing is explosion/blast, water, and chemical proof.

- Internal components and fittings are suitable for installations to 15k psi.

- Nonintrusive capture of data reduces cost.