Decrease Costs and Downtime with Real-Time DFIT Data

Have you ever found yourself sitting in your office wondering how the DFIT you pumped last week was going on your well a thousand miles away? How do you check it? How do you know where you’re at in your test? In the year 2015, we still rely on simple surface and downhole pressure memory gauges to record the pressure for these tests. Typically, this requires a pumper or supervisor to drive hours out to location, just to plug in a computer and get a quick download of the gauge data that then has to be sent back to the engineer and analyzed. The total turnaround from leaving the house to getting the data to performing an analysis can take days if not weeks, not to mention the time and effort spent performing such a simple task. All the while you’re being charged for the gauge to sit out on your well.

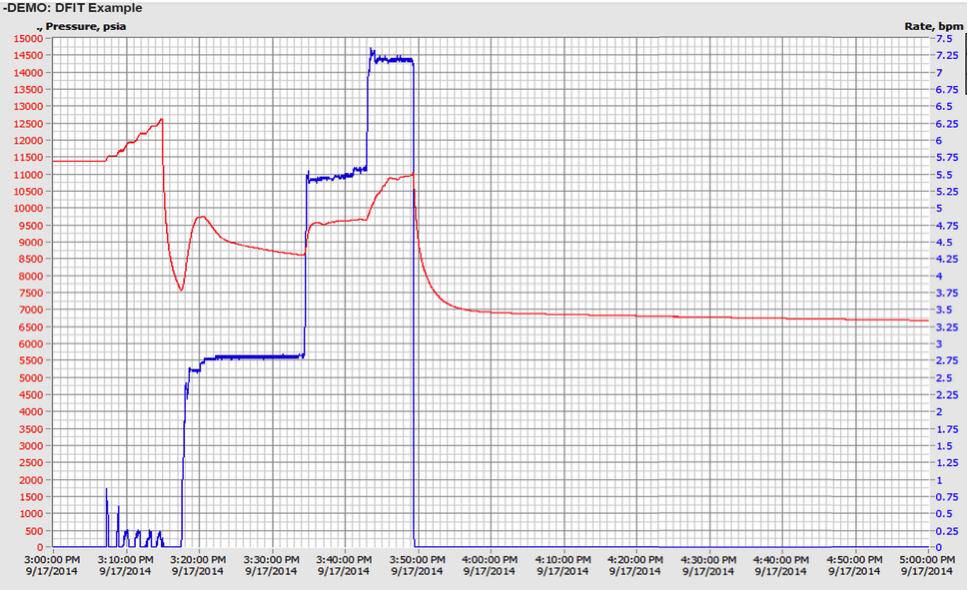

It’s simply unacceptable to live in a connected world with smart phones in our pockets and not have access to your well data. With Reservoir Data System’s FasTrack communication system, the disconnect between the field and office has been eliminated. The FasTrack is the only system that streams the gauge data back to a server that you can access via any internet enabled device (cell phone, tablet, computer), and can even be downloaded while the gauge is still on the well, allowing you to perform your analysis and ensure you have collected enough data before you pull the gauge off the well (this also allows you to end the test early should the well go on vacuum or an outside party interrupt the test). The FasTrack even allows you to set text alerts that will notify you if the well drops below or goes above a desired pressure. Even with an accidental shut-in during the test, you will be notified and be able to remedy the situation immediately.

Having worked as an engineer on the services side of the industry for both frac and gauge service companies, I can’t tell you how many times I’ve heard customers complain that they’ve spent far more money than necessary on a DFIT gone wrong.

For example:

An engineer scheduled a DFIT for 20 days. After receiving the data, he realized that his test was interrupted 5 days prior to ending, and was stuck paying for the wasted rental days.

If the engineer were monitoring his test data in real-time, he could have saved a tremendous amount of money by ending the procedure the day the test was interrupted. The savings on this alone could have allowed for additional well tests.

Although daily gauge rental prices are comparatively low to other expenditures, the cost of a single unit over the course of a 10 or 20 day DFIT or build up can have serious impact— especially if test data is interrupted or the well goes on vacuum.

In the above example, cutting just 5 days of equipment rental could have resulted in a 25% cost reduction. That’s not to mention the wasted time and money spent retrieving and waiting on the gauge data.

Ultimately, the FasTrack is the only system that allows you to access your well tests in real-time, resulting in better quality data, less downtime, and more money in your pocket.

Until next time,

John Kalfayan

Sr. Account Manager, M.E.